CORKLINE®

Key features

CORKLINE represents an equally high-quality, and more affordable, alternative to teak.

Why Corkline®?

- Natural material with an attractive and decorative appearance

- Resistant to atmospherics and seawater

- Resistant to mechanical damage, wear, scratches and stains

- Temperature-persistent (comfortable for walking even at high temperatures)

- Elastic and non-slip

- Easily maintained by standard cleaning agents

- Does not require a complicated and expensive renovation every year

- Easy to install (possible installation under do-it-yourself system)

Corkline® Products

CORKLINE can be purchased in two variants. In the form of slats or in the form of rolls that can be grouted or unfunded.

CORKLINE® planks

CORKLINE® rolls

Corkline® planks

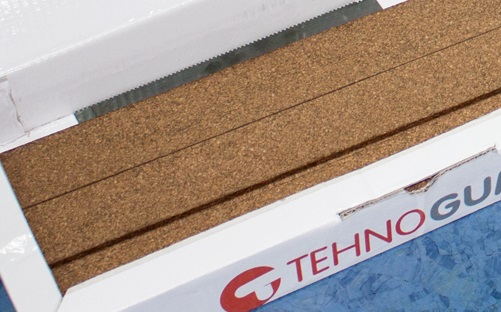

CORKLINE®, in the form of planks, is supplied in different dimensions and packages.

The CORKLINE® 25TG comes in a box containing 20 pcs of slats, 5mm thick, 50mm wide and 1000mm long.

All CORKLINE® products are manufactured from high-quality cork mixed with rubber granules. Although the auxiliary material for installation (pre-preparation, glue, grouting mass) are not part of the standard packaging, they can be specially ordered and delivered together for CORKLINE® packaging.

Corkline Rolls®

Corkline® P5 and PF5 delivered in rolls 5 mm thick, 490 mm wide and 13000 mm long (P5 is not grouting and PF5 is grouted).

Corkline® P8 and PF8 delivered in rolls 8 mm thick, 490 mm wide and 8000 mm long (P8 is not grouted and PF8 is grouted).

All CORKLINE® products are manufactured from high-quality cork mixed with rubber granules. Although the auxiliary material for installation (pre-preparation, glue, grouting mass) are not part of the standard packaging, they can be specially ordered and delivered together for CORKLINE® packaging.

Corkline® dimensions

Corkline slats:

| Item | Dimension | Packaging | MJ |

|---|---|---|---|

| CORKLINE® 25TG | 5 x 50 x 1000 mm | 1 m2/box | box |

Corkline strips:

| Item | Dimension | Packaging | MJ |

|---|---|---|---|

| CORKLINE® L5 | 5 x 70 x 13000 mm | 9.1 m2/pak | m2 |

| CORKLINE® L8 | 8 x 70 x 8000 mm | 5.6 m2/pak | m2 |

Corkline® rolls grouting and with joints unfunded:

| Item | Dimension | Packaging | MJ |

|---|---|---|---|

| CORKLINE® P5 | 5 x 490 x 13000 mm | 6.37 m2/pak | m2 |

| CORKLINE® PF5 | 5 x 490 x 13000 mm | 6.37 m2/pak | m2 |

| CORKLINE® P8 | 8 x 490 x 8000 mm | 3.92 m2/pak | m2 |

| CORKLINE® PF8 | 8 x 490 x 8000 mm | 3.92 m2/pak | m2 |

Corkline® Price Lists

Corkline® Download Documents

CORKLINE – General care and maintenance

Things we recommend

The best time to thoroughly clean the deck is after sailing. Minor impurities resulting from the shedding of various liquids, we recommend to clean immediately. In case you have spilled wine, oil or other liquid on the floor, immediately remove it with a dry cloth and rinse with water. If necessary, use a mild detergent for cleaning.

To remove stubborn impurities, use a mop with suitable inserts, an ordinary scrubbing brush, a pH neutral detergent and water. Stubborn stains and/or mild mechanical damage from the dry surface can be removed with high granulation sandpaper. Grinding gently over the surface of the floor covering to avoid the formation of bumps on the surface of it. This is a very effective procedure that will help keep your floor clean for a long time.

Things we don't recommend

Although the CORKLINE® floor covering is self-extinguishable and flame-resistant, we do not recommend putting hot metals or other hot objects on it. Prolonged exposure of the surface to high temperature can locally cause a change in the color of the surface and the formation of traces.

CORKLINE – INSTALLATION

1. Prepare background

2. Marking

3. Cutting

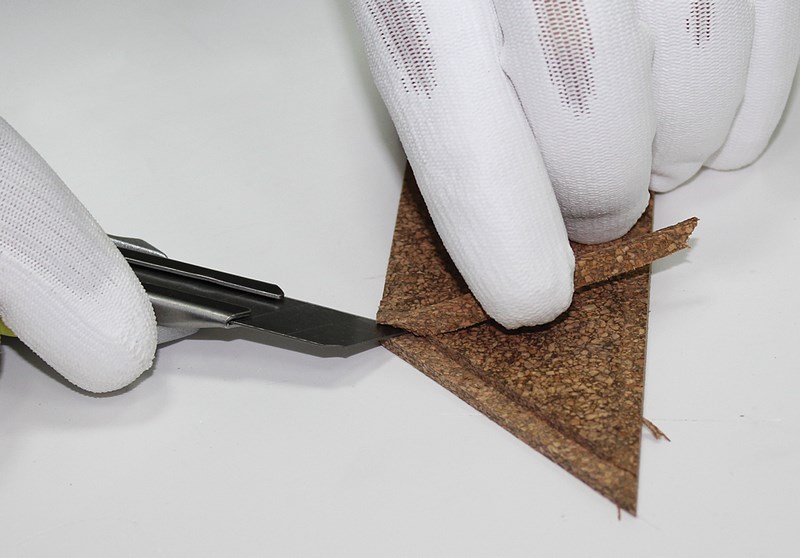

IMPORTANT: When working, be sure to take all precautions. We recommend using protective gloves and using a professional scalpel!!! To ensure a precise joint with adjacent slats, the edges must be sharp and cut off at right angles, which after cutting is achieved with sandpaper processing (we recommend granulation 60-100). Immediately before applying the glue, we recommend that you arrange the CORKLINE® cut slats according to the drawn scheme and thus perform a dimension check.

4. Cutting out joints

IMPORTANT: When working, be sure to take all precautions. We recommend using protective gloves and using a professional scalpel!!!

5. Gluing

NOTE: If you plan to lay CORKLINE® as shown in the picture, before gluing the inner slats, we recommend fixing (gluing) the edge slats (frame) first. After installing the floor covering, excess glue is best removed immediately after installation when it is relatively simple to separate it from the surface. If the glue dries, it is possible to remove it using a special scraper that does not damage the deck.

6. Grouting

NOTE: For grouting, you can use the same material as for gluing. The same is found in the package.

7. Tic oil protection (teak oil)

8. Replacement of damaged slats

PROCEDURE: Cut the damaged slat, in the form of a cross-section, gently to the deck. With a sharp spatula, from the middle to the ends, remove the slat all the way to the edge (the next lamella). Perform the procedure carefully so as not to damage the adjacent lamellae. Remove the remnants of the slat, and thoroughly clean the surface. Install the new lamellae according to the above instructions.

Do you have questions?

Call or send an email inquiry

T: + 385 (0)1 2499 528

E: nauticline@nauticline.hr